Electro-Mechanical Assemblies

Electro-Mechanical Assembly and Box Build Assemblies

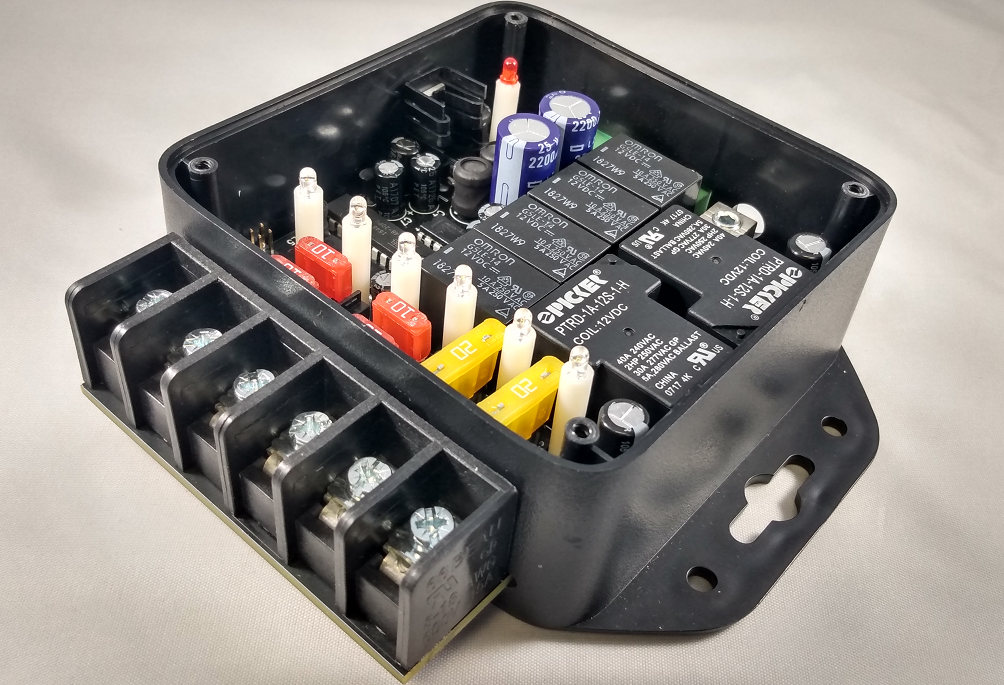

Heltronics serves as a contract manufacturer of electromechanical subassemblies and box build assemblies for OEM and EMS companies. We specialize in complete box build assembly solutions—from trailer-size box builds to small power supplies. For products in robust and harsh industrial environments, Heltronics delivers the highest-quality assemblies manufactured with quality workmanship.

Our custom electromechanical assemblies and box build assemblies include—but are not limited to—the following items.

- Controller Apparatus

- Complete Box Builds

- Power Supplies

- Subassemblies

- Final Assemblies

- Faceplate Assemblies

- Electromedical Diagnostic Apparatus

- Electrotherapeutic Apparatus

As a product that uses electronic and mechanical components to perform a wide spectrum of tasks, electro-mechanical assemblies are vital in the formation of many different common industrial and personal devices. Assembly services for electro-mechanical devices and applications cater to a lot of different niche needs, including electric motor connections and other basic functions, along with more complex tasks like switch control panels. HELTRONICS is a reputable source for creating any level of complexity within an electro-mechanical component and can confidently and professionally assist its clients in forming the perfect product to handle all of their electro-mechanical needs. Let’s take a look at what goes into the electro-mechanical assembly and what a professional grade company like HELTRONICS can do to assist in the electro-mechanical assembly process.

The Benefits of Electro-Mechanical Assembly

While there are other options in the modern market, there are many benefits that come directly from using electro-mechanical assembly to regulate and construct the power supply of most devices. The human approach involving skilled technicians with a keen eye for detail means that each piece is customized and made directly for the job at hand, suiting the client’s needs perfectly.

Electro-mechanical assemblies are found in tons of everyday items that a person experiences in their daily life and in many specialized places that one would not expect. For starters, many computers have electro-mechanical assembly components. Speed sensors for subways and other public transport vehicles also use electro-mechanical assemblies due to their overall reliability and ease of repair. Even the military uses electro-mechanical aspects in weaponry, as it is a quick fix, ready to use application with a low failure rate, which is necessary for such a situation.

Electro-Mechanical Assembly Versus Integrated Circuits

For years, the electro-mechanical assembly method was essentially the only way to make electronic devices. It was effective and did a fantastic job but the resulting products were costly due to the amount of time, effort, labor, and knowledge that went into putting together the individual pieces by hand, including individual wires and minute components. Over time, though, the technologies surrounding the formation of electronic devices evolved, resulting in the creation of integrated circuits, a less labor-intensive system that drastically lowered the cost and manufacturing time of electronic devices. This, in turn, resulted in a dramatic dip in popularity of electro-mechanical assemblies.

Over time, though, there has been a resurgence in interest in electro-mechanical assembly methods. This is due to the limitations that integrated circuits place on a given assembly. For starters, integrated circuits can only handle so much current, making them less than ideal for larger projects. Additionally, low noise and high voltage options are not easily obtained or maintained. It is also more difficult to customize an integrated circuit device since the parts are not easily fabricated. This means larger jobs can be tricky or outright unfeasible depending on the scope of the task at hand.

As an industry-leading electro-mechanical manufacturing company, HELTRONICS is here to assist in creating the exact electro-mechanical components you need to have the best possible final product. All of the components used by HELTRONICS are sourced through other reputable, top brands within the industry that have strong business relationships with HELTRONICS due to their consistent nature of production. As a business that operates on a function of trust, HELTRONICS takes an entirely different approach to create electro-mechanical assembly products, reinventing the wheel to make it faster and more efficient without any dips in quality. In doing this, HELTRONICS can get products to their owners faster, where they can easily be integrated into actual use. They also opt to understand trends in industry technology ad use this information to help them make informed decisions while planning the design of various client products to ensure the longevity and durability of the device, along with ease of upgrade and maintenance for years to come. As a company that looks to serve the clients first, HELTRONICS has the customer’s best interest in mind from start to finish while proving the relevance and power of electro-mechanical manufacturing as more than just a large item assembly technique.

Whether your job is big or small, HELTRONICS has an electro-mechanical plan in mind to help get the results you want and need. The HELTRONICS approach is something wholly new that puts you at the forefront of the design and creates exactly what you need, when you need it, putting you in complete control of your electro-mechanical process experience! Let’s learn more about this unique methodology and approach.

The HELTRONICS Approach

HELTRONICS serves as a contract manufacturer of electromechanical subassemblies and box build assembly products for OEM and EMS companies. Specializing in a complete box build solutions of all sizes, from tiny components to massive, trailer size panels, the company can handle anything a brand may need in regards to box builds and electro-mechanical assemblies. This diverse ability coupled with the professional and experienced team members provides an incredibly effective and efficient electro-mechanical assembly firm that can get the job done! Generally, there are two common electro-mechanical assembly jobs: box building and control panel assembly.

About Box Build Assemblies

A box build assembly, at its essence, is an inclusive descriptor used to describe the process of manufacturing everything aside from the printed circuit board. Also referred to as a systems integration, this is an all-encompassing product that creates everything a business needs aside from the base manufactured circuit board to help curate the perfect, individualized electro-mechanical set up for the given tasks at hand.

Done to accompany the printed circuit board assembly or PCBA, this process includes a wide range of individual services. This includes:

- System Assembly

- Product Assembly

- Sub-product Assembly

- Labelling

- Packaging

- All Necessary Testing

- Software Installation and Testing

- Product Configurations

- Software Configurations

- Warehouse Storage

- Order Fulfilment

- Repair

- Refurbishment

- After-Market Guidance

- And more!

Since HELTRONICS specializes in complete box builds, they handle all of these facets to create the perfect final device to suit all of a given business’s needs, no matter what they may be, giving businesses the confidence and peace of mind needed to achieve truly great things.

The company also works to cut down on the development time of the project by thoroughly planning the installation and build before beginning to create a concrete path to success. This includes measurements like the size and weight is decided ahead of time and the routing of cabling being mapped out in advance, among other facets of the assembly’s planning. This gives HELTRONICS the means to quickly move through putting everything together without cutting corners or sacrificing quality in any way, shape, or form. The expedited turnaround is simply a by-product of having a well-rounded plan.

About Control Panels

Electro-mechanical control panels are designed to control pieces of equipment on a job site or other venue. These pieces of equipment can range from small drones to more intrusive pieces like transit vehicles and includes devices that allow operators to control equipment remotely. Most companies rely on an electro-mechanical control panel in one way or another and it is one of the widest spread pieces of machinery available today. Due to this, almost every industry can benefit from upgrades or new pieces, leading to the demand for control panels being one of the largest. This often translates to longer wait times for service requests but, thanks to Heltronic’s fast turnaround times, the issue is negated through a system of carefully chosen and professional venues to ensure the product gets to the client as soon as possible!

Adding an electro-mechanical control panel to a job site can not only expedite the work process but also work to reduce the overall risks that come with the job. Having a control panel on site that can turn things on and off at the flip of a switch or press of a button can prevent accidents and keep things safe and secure on the job site. Due to this, more and more businesses are investing in a minimum of a single control panel to act as an emergency shutoff or other similar application. Aside from this, there is a multitude of benefits that can come from using control panels, including a simple increase in general efficiency. HELTRONICS is here to help get companies on their way to experiencing a safer, easier workspace!

HELTRONICS: Electro-Mechanical Experts

HELTRONICS has served the Eastern Pennsylvania area, specifically from Berks County, since its establishment in 2008. As a custom manufacturing one-stop-shop, HELTRONICS provides a wide range of services, ranging from Control Panel Assemblies, Wire and Cable Harnesses, Repair and Refurbishment Services, and Complete Engineering and Product Design to professional-grade Electro-Mechanical services. This diverse product catalog allows HELTRONICS to service all of their client’s needs, catering to a massive spectrum of businesses and individuals in need of expert advice and knowledge.

The experienced staff provides technical education to clients along with their manufacturing services to help them truly understand what is happening within their devices. This allows them to mitigate issues and understand when to call in professionals to help in the future. Additionally, HELTRONICS understands obsolescence and plans ahead to ensure there is room for growth, advancement, and updating within the projects they take on. This greatly extends the overall life of the product and saves clients money and time in the long run by making it easier to work on existing products to match the industry-standard instead of creating something wholly new every time a new and potentially helpful piece of technology becomes available.

Regardless of what you need, HELTRONICS is ready to help you achieve your goals and make the most of every aspect of your job site or personal custom manufacturing project. As a company dedicated to serving the community that has supported it for so many years, clients can count on HELTRONICS to always deliver the highest quality products in the shortest amount of time at an affordable rate. HELTRONICS is here to help!

How I can contact you?

In order for us to give you an exact quote, please use our contact form. There you can submit drawings, pictures and Bill of Materials (BOM).

How I can get the list of your products?

Send us any drawing, pictures and files for us to define the right product for your requirements.

Who are your industrial partners?

We use a variety of vendors, all reviewed and used for many years. All having a long term relationship with Heltronics Inc. and a proven track record with delivery and quality.

What is An Electro-Mechanical Assembly?

In a nutshell, electro-mechanical assemblies are used to put together electric and mechanical components that are necessary to complete a task. Every electro-mechanical assembly is a delicate task that requires careful engineering, planning, and installation to work properly. All of the pieces must work in tandem to generate the desired effect, be it something like turning on a light or triggering a series of different operations. Common electro-mechanical assemblies include:

- Controller Apparatus

- Complete Box Builds

- Power Supplies

- Subassemblies

- Final Assemblies

- Faceplate Assemblies

- Electromedical Diagnostic Apparatus

- Electrotherapeutic Apparatus

- And much more

Needless to say, these devices provide vital functions for many basic and complex electronic devices. That being said, many operations once moderated by an electro-mechanical assembly can now be completed through integrated electronic circuits instead, simplifying the process further. Still, many people do prefer electro-mechanical assemblies due to repair and upgrade options.

Typically, electro-mechanical assemblies are used to regulate the power distribution of AC and DC currents, function as general control systems, and act within certain computer interfaces. All of these applications are viable, great ways to utilize this method of electric regulation.

Due to the complexity of these designs and the overall need for the ability to fine-tune each wire and detail, electro-mechanical assemblies are usually done entirely by hand, requiring a special level of skill and knowledge to successfully be completed. These technicians are fully trained in mitigating issues and solving problems themselves, drastically reducing the turnaround time for each given project. With a wide range of skills including soldering, wire organization, and other basic facets, these technicians are a vital part of the HELTRONICS team and play a massive role in ensuring every single electro-mechanical assembly project is completed to the highest possible tier of quality.